Reducing the impact on our environment requires materials and not just how we use the products but where they came from and where they are going.

- energy used to make, ship and apply a product

- the products contents and the sources of its raw materials

- emissions during manufacturing the product and the level and type of toxins in the final product

- the products durability and recycleability

- location on material and fuels use for transportation

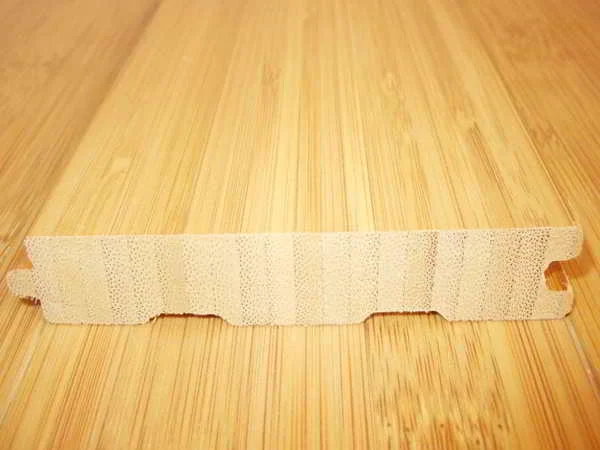

Renewable material like bamboo which is a fast grass which grows much faster than wood, can be harvested without replanting because of its root system, is strong, durable, and resists insects and moisture.

Recycle finish materials like countertops made from recycled glass, stone and plastics. Reclaimed wood flooring, recycled glass, stone and plastic flooring and wall tiles, recycled plastic and wood decking are indistinguishable from their non-recycled counterparts.

Low / Zero Volatile Organic Compounds (VOC)

VOC's are organic chemicals that have a high vapor pressure at ordinary room temperature. Some VOC's dangerous to human health or cause harm to the environment.

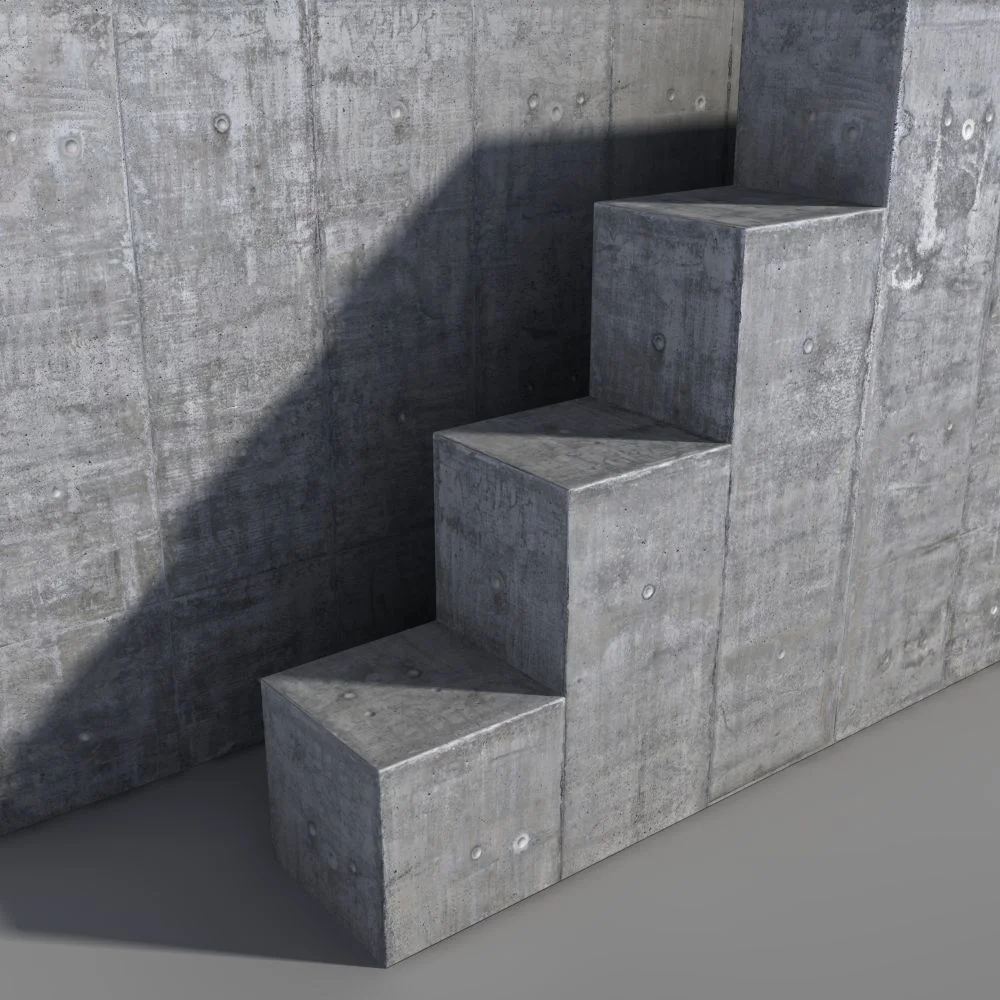

Durable

Concrete is not only durable provide a thermal mass, high in compression strength, reflectivity, and produced pervious for environmental needs, and allows for minimal waste and recycled for use as aggregate in new concrete. It is comprised of limestone the most abundant mineral on earth, and made from fly ash, slag cement, and silica fume which are all wast byproducts from manufacturing facilities.

Steel Siding

Besides being an extremely durable product, over 80% of steel is recycled, compared to 53% of aluminum and less that 10% of the plastic.

Insulation

There are many types of insulation for different conditions i.e.compression - under slabs or roof membranes; gap infill - utility penetrations, conduit through wall; sound absorption - walls adjacent bedrooms or conference rooms. And there are many insulation comprised of green materials such as cotton, wool, and castor oil.